Is automotive-grade solid-state battery ready to be used soon?

Even novices understand that in the era of new energy vehicles, whoever can solve the three major challenges of battery charging, energy storage, and endurance will become the leader of this era.

Although these three major challenges do not yet have standard answers, the faster the charging, the higher the energy storage, and the more stable the endurance, the higher the competitiveness will be!

Currently, new energy vehicles on the market generally use semi-solid-state batteries, so everyone’s hope is placed on solid-state batteries. Many related enterprises and automakers are also investing in research and development in this area.

What is an all-solid-state battery?

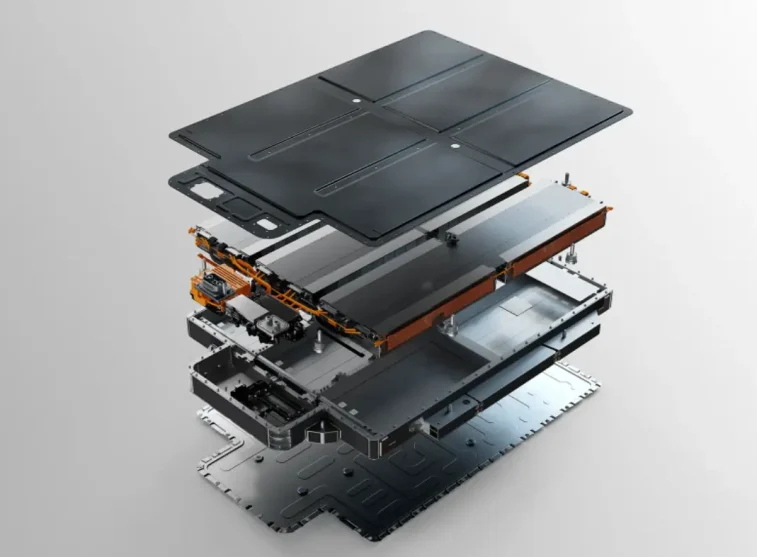

Simply put, all materials that make up the battery are solid-state. In contrast, the structure of current automotive-grade semi-solid-state batteries consists of one electrode side without liquid electrolyte, while the other electrode side contains liquid electrolyte.

In comparison, solid-state batteries offer advantages such as high energy density, strong cycling performance, high tolerance to extreme temperatures, no leakage, and improved safety. The current issues of “rapid degradation in high/low temperatures” and “overstated range” in new energy vehicles stem from the fact that they do not possess the characteristics of solid-state batteries.

Are all-solid-state batteries in mass production?

In fact, solid-state batteries have been applied in multiple fields, but there is currently no mass-produced commercial-grade solid-state battery available.

Although in January this year, ProLogium Technology (China Taiwan) announced the production of the world’s first automotive-grade solid-state battery production line (in Taoyuan, Taiwan), claiming that the new large lithium ceramic battery can be charged to 80% in just 12 minutes, achieving a range of 1000 kilometers and a cycle life of over 1000 times.

However, ProLogium Technology also provided data indicating an annual production capacity of 26,000 units. Currently, this capacity falls far short of meeting the production and sales pace of new energy vehicles.

However, the recently unveiled IM Motors L6 claims to use solid-state batteries, boasting a nearly 900V high-voltage fast charging capability and a range of over 1000 kilometers!

According to the data released by IM Motors L6, the MAX standard version uses lithium iron phosphate batteries (from Contemporary Amperex Technology) and ternary lithium batteries (from CATL), with ranges of 650 kilometers and 780 kilometers, respectively. However, no information regarding solid-state batteries has been provided.

CATL

However, during the performance interpretation meeting of CATL in March this year, Zeng Yuqun stated that, technically, solid-state batteries still face many fundamental scientific issues such as solid-state ion diffusion, and they are far from being commercialized.

We also need to understand that there is an “impossible triangle” in the field of power batteries, which means combining “higher energy density, higher safety, and lower cost” into one battery.

This implies that with the current battery technology, even if mass-produced, high-energy-density, high-safety vehicle-grade solid-state batteries, consumers with ordinary income may not be able to afford them!

This involves research and development investment, material costs, manufacturing costs, and so on. In fact, in the eyes of some industry insiders, rather than focusing on developing vehicle-grade solid-state batteries, it might be more worthwhile to directly leapfrog to hydrogen fuel cells.

According to information released by Sinopec, the company has already reduced the production cost of hydrogen to 1.3 yuan per cubic meter. If they can solve the technical challenges related to transportation, storage, application, and safety on this basis, I believe it would be more worthwhile to vigorously develop hydrogen fuel cells than solid-state batteries. What do you think?